|

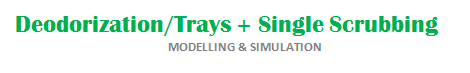

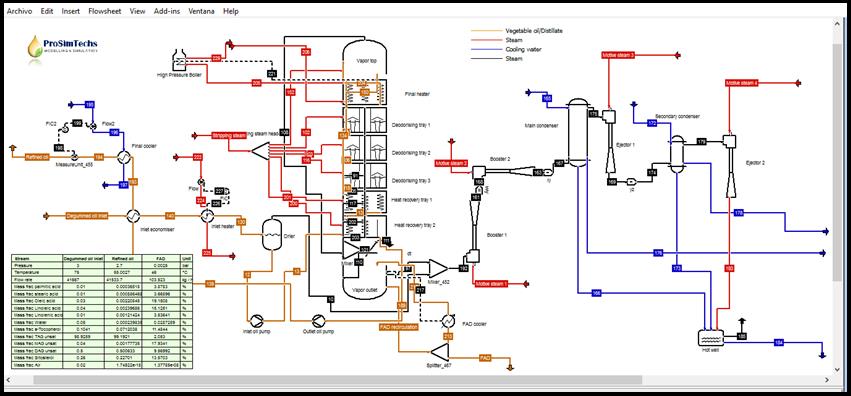

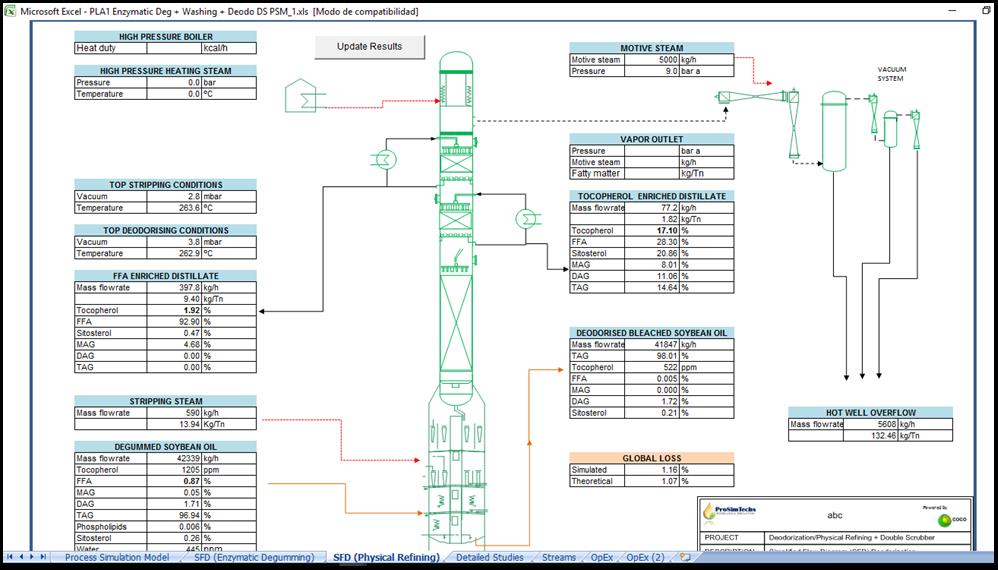

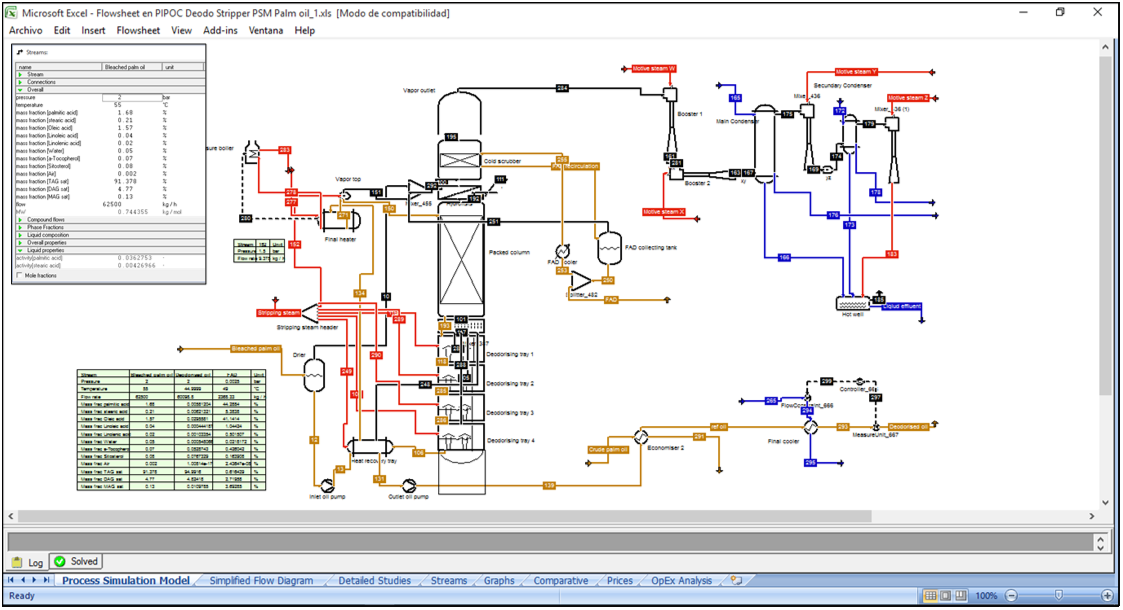

Our Deodorization models take into consideration column details as per structured packing section, steam lift pump trays, sinngle or doublé scrubbers, for any type of vegetable oil (soybean oil, rapeseed oil, palm oil, etc)

Deodoriser is modelled as a stage-to-stage column, it is feasible to calculate and to analyze the traffic of compounds inside the column. Vacuum system can be also modelled considering whether is a indirect or direct, cooling or chilled water, or and ice condensing system. |

|

A simulation run allows to determine best processing scenario in terms outlet streams composition, oil yield and process conditions (stripping temperature, stripping steam, vacuum). The process model allows us to get a deep knowledge about what is talking place inside the column, and to make process decisions. |

|

2016 © Process Simulation Technics |

|

ACTUAL VEGETABLE OIL COMPOSITION |

|

DIFFERENT VACCUM SYSTEMS |

|

DEODOROISER AS STAGE TO STAGE MODEL (NOT BLACK BOX) |

|

ADJUSTING LOOPS |

|

GLYCERIDES HYDROLISIS AND TOCOPHEROL DEGRADATION MODELS |

|

OIL YIELD (OIL LOSSES DIAGNOSE) |

|

SIMGLE OR DOUBLE SCRUBBER MODEL |

|

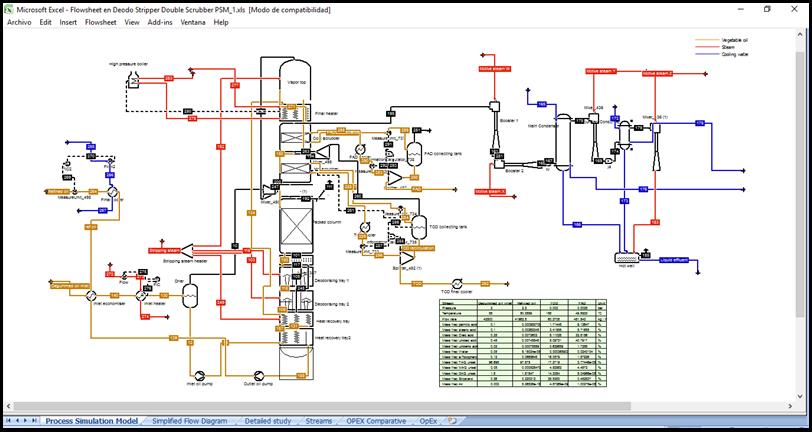

Simplified Flow Diagram |

|

Relevant process information is extracted from the Process Simulation Model (PSM) to a Simplified Process Model (SPM), considering main streams and key equipment, for specific analysis of simulation results. |

|

Process Simulation Model (PSM) |

|

OIL YIELD (OIL LOSSES DIAGNOSE) |

|

HOME | SOLUTIONS | STUDIES | CONTACT US | ABOUT US |