|

Process Simulation Models |

|

ProSimTechs specializes in software development of process simulation for use in process optimization tasks.

Using ProSimTechs technology it is possible to diagnose current processing scenario of the plant, as well as to significantly improve the operation and design, for example, by minimizing neutral oil losses, steam consumption and reducing environmental impact while improving vegetable oil quality.

The technology also allows benchmarking of process performance and provides an effective and efficient troubleshooting tool for process engineers. |

|

2016 © Process Simulation Technics |

|

Our process simulation models, powered by COFE, run entirely in MS Excel® environment, allowing to extract process simulation information for further analysis.

|

|

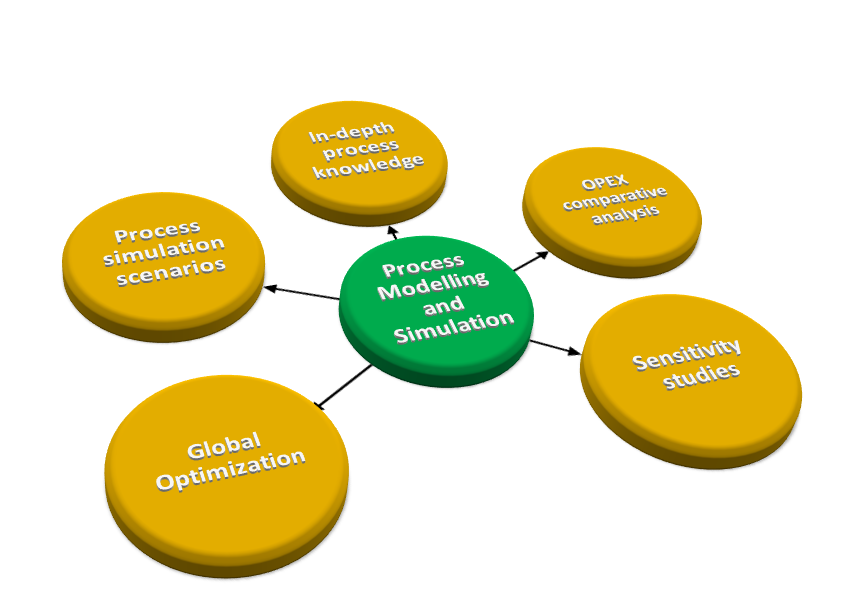

Process Modelling and Simulation (What you can get) |

|

Advanced Process Simulation & Modelling |

|

How many optimization industrial trials do you have to run, for instance in a Deodorization, to change only stripping temperature from 240 to 250 °C and stripping steam mass flowrate from 8 to 10 kg/Tn aiming to analyze the impact on FFA mass concentration in deodorized oil and distillates ? 3 times 3 (=9) at least ? How long do these trials take ? What is the cost involved if we put in risk the oil quality ? And the cost of lab analysis ?

Do it simpler, faster and safer with Process Simulation from ProSimTechs |

|

HOME | SOLUTIONS | STUDIES | $$ CASES | CONTACT US | ABOUT US |

|

In ProSimTechs we have put all our efforts to bring excellence solutions to your process optimization needs.

That is why we have developed High-fidelity simulations models to cover all minor details for both equipment and process details, to achieve realistic results and to bring a real added value to your process optimization tasks.

Our process simulation models are built in a tailor-made way, taking into account type of vegetable oil, technology and P&IDs. |