|

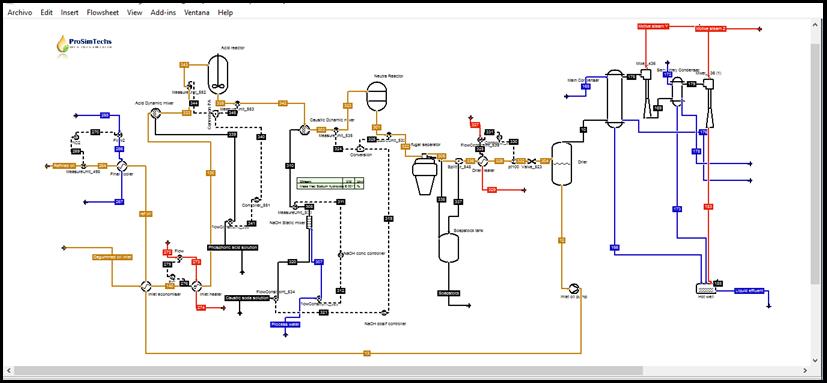

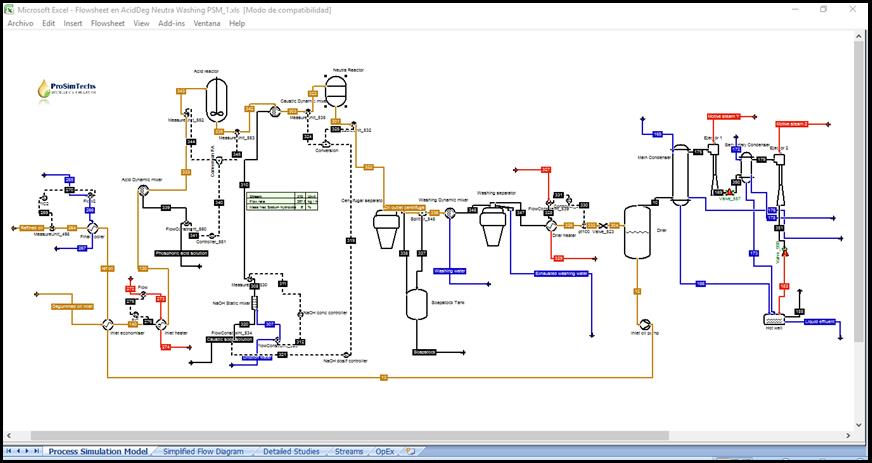

A simulation run allows to determine best processing scenario in terms outlet streams composition, oil yield and process conditions. The process model allows us to get a deep knowledge about what is talking place along the process, and to make process decisions. |

|

Complete phospholipid salts acid reactions (non hydratable to hydratable) are considered for each type of phospholipid including a given conversion degree adjusting acid solution required and its† excess. Free fatty acids neutralization reactions are also considered for each specie† (oleic acid, stearic acid, palmitic acid, etc) with caustic soda solution and a given percentage of dilution water. |

|

2016 © Process Simulation Technics |

|

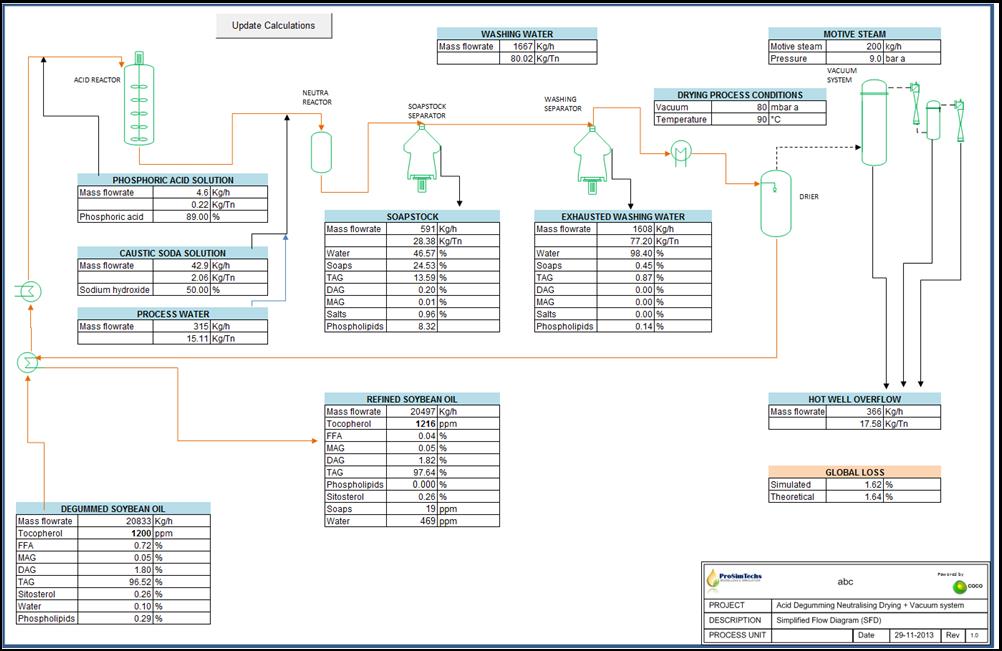

Simplified Flow Diagram (SFD) |

|

ACTUAL VEGETABLE OIL COMPOSITION |

|

ACID REACTIONS |

|

Relevant results for main streams are exported to a simplified flow diagram for specific analysis like oil yield, soapstock composition, soapstock and phospholipid residual in neutralized oil, etc. |

|

OIL YIELD (OIL LOSSES DIAGNOSE) |

|

WASTEWATER GENERATION |

|

SOAPSTOCK COMPOSITION |

|

CENTRIFUGE EFFICIECY FOR EACH COMPOUND |

|

NEUTRALIZATION REACTIONS |